The role of Pipeline services Midland Texas in reducing costs

Wiki Article

Recognizing the Trick Functions of Pipeline Services and Their Impact on Efficiency

Pipeline solutions play an important duty in various sectors, affecting operational performance markedly. Secret attributes, such as innovative tracking technologies and upkeep strategies, are essential for minimizing downtime. In addition, governing conformity assurances safety and environmental management. However, the interaction between layout, infrastructure, and financial variables can complicate these processes. Understanding just how these elements effect general performance increases essential concerns concerning best practices and future developments in the field.The Duty of Technology in Pipeline Monitoring

As innovations in technology proceed to advance, the relevance of effective pipeline monitoring has actually become progressively noticeable. Modern pipeline systems count on sophisticated monitoring devices that improve operational efficiency and safety. Technologies such as real-time data analytics, sensing units, and drones offer drivers with immediate understandings right into pipe problems, allowing them to spot leaks, rust, and various other possible problems before they intensify into considerable troubles.Furthermore, the combination of Internet of Points (IoT) devices has actually changed traditional surveillance techniques, permitting continual monitoring and automated reporting. This positive technique not just reduces dangers but also enhances upkeep routines and resource allotment. In addition, advanced software program platforms assist in data visualization and interpretation, empowering decision-makers to react swiftly to abnormalities. Collectively, these technological innovations not only enhance pipe stability however also foster ecological stewardship by alleviating the prospective effect of leakages and spills.

Upkeep Approaches for Enhanced Performance

Effective maintenance techniques are vital for maximizing pipe effectiveness. Executing predictive upkeep strategies, adhering to routine inspection procedures, and creating durable emergency situation action plans can significantly improve functional reliability. These approaches not just lessen downtime but also add to the general security and integrity of pipe systems.Anticipating Maintenance Methods

Predictive upkeep strategies are increasingly recognized for their capability to enhance operational effectiveness in pipeline services. By leveraging information analytics and keeping an eye on innovations, these methods make it possible for operators to anticipate equipment failings before they take place. This proactive method lessens unintended downtime, reduces upkeep prices, and extends the life expectancy of important properties. Sensing units and IoT gadgets play a pivotal role in gathering real-time data, permitting the evaluation of equipment health and wellness and performance trends. Artificial intelligence formulas analyze this data to determine patterns and anticipate prospective problems. Pipeline operators can arrange upkeep tasks throughout non-peak times, maximizing resource allocation and ensuring constant operation. Eventually, the fostering of anticipating upkeep promotes a more reliable and efficient pipeline framework.

Regular Assessment Protocols

Routine evaluation procedures act as a keystone of maintenance techniques focused on enhancing performance in pipeline procedures - Pipeline services Midland Texas. These methods include methodical analyses of pipeline honesty, concentrating on finding prospective concerns prior to they intensify. Routine assessments generally consist of visual evaluations, leak discovery modern technologies, and stress surveillance to ensure peak efficiency. By adhering to well-known timetables, operators can recognize rust, material wear, or blockage, therefore decreasing downtime and fixing prices. Furthermore, information accumulated during examinations can inform predictive upkeep initiatives, permitting for a positive approach to pipe management. Inevitably, regular examinations not just expand the lifespan of pipe framework yet additionally add to much safer and more reputable transportation of sources, enhancing overall functional performanceEmergency Reaction Preparation

Emergency situation feedback preparation is necessary for maintaining effectiveness in pipe operations, making certain that drivers are prepared to resolve unforeseen incidents promptly and efficiently. A well-structured emergency response strategy includes clear protocols, marked functions, and interaction techniques to mitigate risks connected with pipeline failings. Normal drills and training boost team readiness and acquaint workers with emergency treatments. Furthermore, having conveniently offered resources, such as spill containment devices and emergency call lists, can considerably lower feedback times. By integrating real-time monitoring innovations, drivers can quickly determine and react to concerns, minimizing environmental influence and operational downtime. Inevitably, an extensive emergency response plan not just safeguards assets and personnel but also strengthens the total efficiency of pipe solutions.Governing Conformity and Safety Requirements

Regulative compliance and safety and security standards play a crucial role in the pipeline services sector. Creek Pipe local contractor. Following sector regulations guarantees that companies implement efficient safety protocols and run the risk of administration strategies. This dedication not only safeguards workers and the setting but likewise boosts overall operational efficiencyConformity With Sector Regulations

Compliance with industry laws is crucial for making certain the safety and security and performance of pipe operations. Regulative frameworks, such as those established by the Epa (EPA) and the Pipeline and Hazardous Products Safety And Security Administration (PHMSA), established stringent criteria that drivers need to stick to. These laws cover numerous elements, including pipeline design, building and construction, maintenance, and monitoring, ensuring that systems operate safely and properly. Non-compliance can lead to severe penalties, operational hold-ups, and ecological dangers. By sticking to these laws, pipe companies not just shield public security and the environment yet also improve their functional efficiency. Inevitably, governing conformity fosters trust fund amongst stakeholders, ensuring that pipeline solutions can operate effortlessly in a competitive landscape while meeting lawful commitments.

Safety Procedure Application

Effective security method implementation is an important element of pipeline procedures, closely connected to regulatory conformity and security criteria. Complying with these methods not just ensures the security of employees however additionally safeguards the atmosphere and infrastructure. A durable safety and security structure consists of routine training, thorough inspections, and the use of suitable safety and security devices. Organizations should stay attentive in upgrading their procedures to show modifications in policies and technical advancements. Conformity with well established security standards decreases the threat of mishaps and boosts operational efficiency. Furthermore, a culture of safety and security promotes staff member involvement and liability, contributing to overall business success. Inevitably, reliable security protocol application is paramount in maintaining the stability of pipe solutions and attaining long-term sustainability in operations.Danger Monitoring Strategies

Implementing robust risk management techniques is important for guaranteeing that pipeline procedures stick to regulative needs and safety standards. Organizations must identify prospective hazards and examine threats connected with pipe activities. This includes conducting thorough assessments, making use of innovative monitoring innovations, and keeping compliance with sector laws. Routine training for workers on safety and security methods enhances situational awareness and prepares groups to respond properly to emergency situations. In addition, establishing backup plans and performing drills can substantially reduce threats. Working together with governing bodies ensures positioning with evolving safety and security requirements. By prioritizing risk monitoring, pipeline solutions can boost functional efficiency while protecting both the atmosphere and public security. Ultimately, a proactive strategy to take the chance of monitoring fosters a society of safety and security within the sector.Pipeline Layout and Facilities Considerations

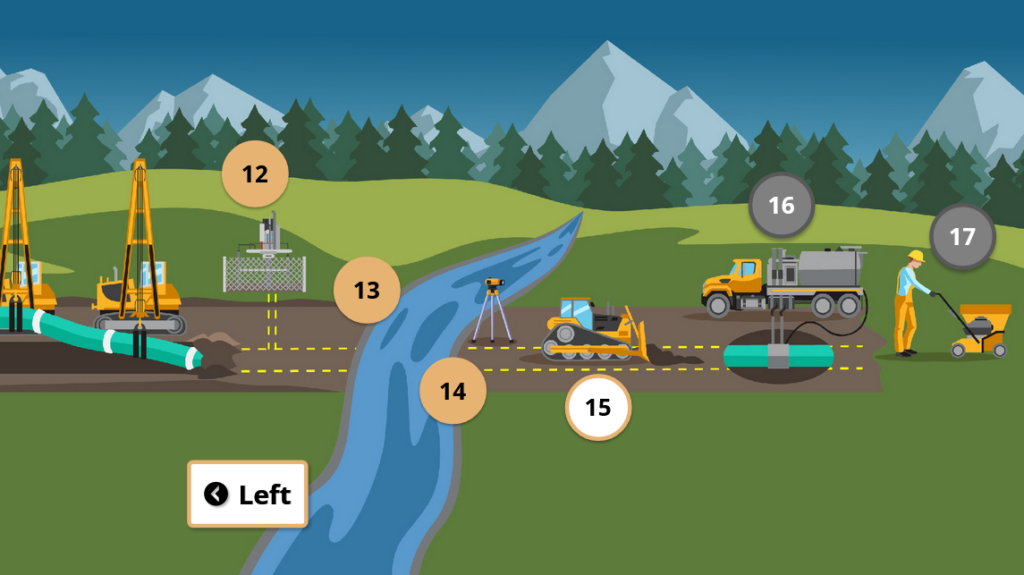

How can the layout and facilities of pipelines influence overall operational efficiency? The configuration of pipes plays an important role in identifying their effectiveness. Effective style decreases rubbing losses, hence reducing power consumption during liquid transport. Elements such as diameter, product option, and format straight influence circulation prices and upkeep demands.In addition, calculated placement of shutoffs and keeping an eye on systems enhances functional control and safety. Midland pipeline construction company. Infrastructure considerations, consisting of availability for upkeep and repair, substantially affect downtime and general performance

Incorporating innovative modern technology for real-time surveillance promotes timely discovery of leakages or inadequacies, making sure quick reactions to issues. The overall structural integrity, affected by material toughness and ecological variables, additionally shapes long-term operational success. As a result, thoughtful style and durable infrastructure are essential for optimizing pipe effectiveness, eventually adding to the dependability and profitability of pipe solutions.

Ecological Influence and Sustainability Practices

While the need for pipeline services remains to grow, recognizing the ecological effect and adopting sustainability techniques has come to be progressively crucial. The building and construction and operation of pipes can significantly influence environments, wildlife environments, and water resources. To reduce these impacts, firms are applying sophisticated technologies and techniques targeted at reducing emissions, stopping spills, and lessening land disturbance.

Sustainability initiatives typically consist of utilizing eco-friendly materials, improving power efficiency, and utilizing renewable resource resources to power procedures. In addition, companies are increasingly performing comprehensive ecological analyses before project initiation, guaranteeing compliance with guidelines and stakeholder engagement.

Price Management and Financial Variables in Pipeline Providers

As the pipe industry expands, reliable cost management and recognizing economic elements come to be necessary for keeping competitiveness. Firms face various economic pressures, consisting of changing product expenses, labor expenditures, and regulative conformity fees. To browse these obstacles, pipeline service carriers must adopt critical financial preparation and budgeting practices.Spending in technology can boost operational performance, eventually lowering costs gradually. In addition, reliable task administration warranties that resources are allocated successfully, reducing hold-ups and unanticipated costs.

Market conditions, such as need for power and geopolitical factors, additionally affect financial feasibility. Firms have to continue to be nimble, changing their techniques in response to these outside aspects.

Regularly Asked Questions

What Are the Various Sorts Of Pipeline Provider Available?

Numerous kinds Midland oilfield pipeline services of pipe services include transport, storage space, maintenance, assessment, and repair. Each solution plays an essential function in guaranteeing the smooth motion of materials, boosting safety and security, and minimizing functional disturbances across various industries.Just How Typically Should Pipeline Inspections Be Conducted?

Pipeline examinations must be carried out frequently, normally each to three years, depending upon the type and problem of the pipeline. More frequent evaluations might be required for older or risky pipelines to guarantee safety and security and integrity.

What Are the Key Causes of Pipeline Failures?

The major root causes of pipe failures include corrosion, defective construction, material flaws, external damages, leaks, and operational errors. Each variable contributes significantly to possible risks, highlighting the significance of routine upkeep and surveillance for safety and security.Just How Can Companies Improve Pipeline Service Reliability?

Firms can boost pipe solution dependability by carrying out normal maintenance routines, utilizing sophisticated surveillance technologies, performing thorough examinations, investing in employee training, and taking on positive danger management techniques to anticipate and alleviate potential failings.What Role Do Operators Play in Pipeline Solutions?

Operators play an essential role in pipeline services by guaranteeing risk-free transportation, preserving devices, keeping track of system stability, collaborating upkeep, and reacting to emergency situations. Their knowledge straight affects functional performance and lessens interruptions in solution delivery.Report this wiki page